The Company's core technology is the pneumatic suction pump. The pump adopts the working principle of piston, and sequentially opens and closes the valve parts, sucking continuously and therefore discharging mud. The mud inletting is driven by the negative pressure difference generated by the water depth and mud discharge is driven by compressed air, which is different from the impeller rotating centrifugal pump or mechanical transmission of conventional dredger.

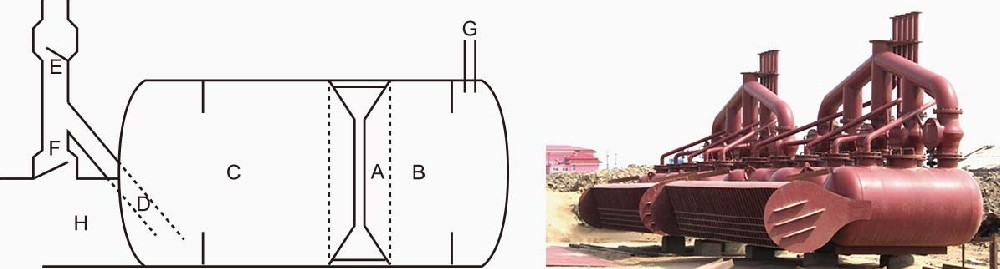

The pump body of the pneumatic suction pump is a long cylinder, the middle of which is a movable circular partition A (piston plate), and the two ends of which are the mud inlet and outlet space C and the air charging and discharging space B. A steel pipe D is connected to the mud inlet and outlet space, and the upper and lower ends of the steel pipe are provided with piston plates of the same direction, which are the mud discharge valve E and mud inlet valve F. Valve E and F are connected to the suction shovel H and mud discharge pipe.

The pump body is placed at the bottom of the water. When it discharges air, the circular partition would move to the air charging and discharging space by the bottom pressure, then the mud discharge valve would close and mud inlet valve would open, and the mud enters; when it charges air, under the high-pressure air thrust, the circular partition would move toward the mud inlet and outlet space, then the mud inlet valve would close and mud outlet valve would open, and the mud is discharged.

A set of pneumatic suction pump consists of 3 to 4 pump bodies. The pump bodies would charge and discharge air in sequence to form continuous process of mud inlet and discharge.